Customer’s Choice: the Best Rated Soldering Iron Holders

[survey_answers id=”814264127″ style=”plain” data=”score”] users answered this survey. Please help us improve this review!

[survey_answers id=”814264127″ style=”piechart” legend=”true”]

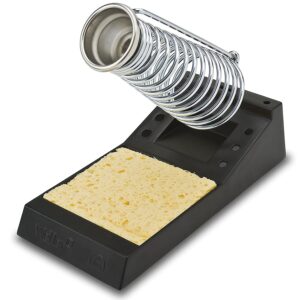

Elenco Soldering Iron Holder – the best Editor’s choice!

The Elenco Soldering Iron Holder will keep your soldering iron away from damaging surfaces with its two coiled springs. The metal base not only helps provide stability during use but also acts as a durable casing for this useful device!

The Elenco Soldering Iron Holder will keep your soldering iron away from damaging surfaces with its two coiled springs. The metal base not only helps provide stability during use but also acts as a durable casing for this useful device!

This holder is easy to install due to its stand and rubber-lined ends that grip most surfaces, even carpeting. Finally, the sponge tip cleaner at the top of the rod provides you with an affordable way to clean solder tips!

Pros

- Easy to install;

- Includes a sponge for tip cleaning;

- Stable and durable metal base;

- Protects users from burns;

Cons

- Too light for heavy soldering irons;

- The base is too thin;

- No good finish;

The Elenco Soldering Iron Holder is just what you need when high quality sells great for a low price all in one place. If you’re looking for a reliable, stable, all-around good guy soldering iron holder, this is the one!

Hakko 633-01 Iron Holder – the best for handheld soldering irons!

Keep your soldering iron at the ready with this essential must-have. The Hakko 633-01 Iron Holder is a nifty solution for any surfer of electronics in need to solder on the go.

Keep your soldering iron at the ready with this essential must-have. The Hakko 633-01 Iron Holder is a nifty solution for any surfer of electronics in need to solder on the go.

With a simple construction made from stainless steel, you’ll be able to safely and easily store your iron with neat efficiency. It has a cleaning wire pot attached so that it can collect solder residue, making cleanup quick and easy. This model can hold all handheld soldering irons – like the Hakko FX650 DASH – with its small lightweight design for portability around your workspace as well.

Pros

- Good for handheld soldering irons;

- Small lightweight design;

- Made with stainless steel;

- Includes a cleaning wire pot;

Cons

- Not compatible with some popular tools;

- The cup is not secured to the holder;

The Hakko Iron Holder is here to save your space and protect you from injury. This iron holder has a narrow design with a cleaning wire pot, which makes it perfect for tabletop use! It is home-friendly too because of its small size.

Trusco Goot Soldering Iron Stand ST-11 – the best for ceramic soldering irons!

This sturdy and stylish Soldering Iron Stand is guaranteed to make your life easier. It holds any type of soldering iron with a sponge pad large enough to cover the entire iron and a thick base for stability.

This sturdy and stylish Soldering Iron Stand is guaranteed to make your life easier. It holds any type of soldering iron with a sponge pad large enough to cover the entire iron and a thick base for stability.

Safe for use in many positions, this stand features a tough single-coil that can go anywhere you need it — without worry about metal touching metal during use.

The Trusco Goot Soldering Iron Stand can be the perfect way to keep your iron in place during those long soldering sessions.

Pros

- Large;

- Designed for nichrome and ceramic soldering irons;

- Sturdy and stylish;

- The large sponge pad;

Cons

- Risk of burning from contacts;

This Trusco Goot solder stand with a sponge pad and an isolated power cord makes it perfect for any type of soldering iron.

Weller PH100 Stand Fits W100PG – the best for Weller soldering irons!

The stand from Weller is the only way you should ever consider storing your iron. It provides ultimate heat-dissipating and stability due to its heavy weight. Getting this setup was quick and easy – perfect if you’re not exactly meticulous about using instructions (not included).

The stand from Weller is the only way you should ever consider storing your iron. It provides ultimate heat-dissipating and stability due to its heavy weight. Getting this setup was quick and easy – perfect if you’re not exactly meticulous about using instructions (not included).

Leverage the power of your Weller irons in style and comfort. This must-have soldering stand is large enough for all of the models from 80 to 120 watts, has a heat dissipating material to keep your iron at the optimum temperature, and provides quick and easy assembly.

Pros

- Built with 100% metal;

- Quick to assemble;

- Fast heat dissipation;

- Good for Weller 80, 100 and 120-Watt irons;

Cons

- No detailed instructions;

- Heavy;

This is just the kind of tool everyone needs to protect their soldering iron. The perfect combination of quality and affordability, this Weller product will make securing your iron to any worktable a breeze!

Weller PH60 Iron Stand – the best for large soldering irons!

This Weller PH60 stand is for those who use a large soldering iron while working. It will make the job much easier because it aligns your hand just right to the tip of the iron. You are not confined in any one position and you can access every solder seam with ease.

This Weller PH60 stand is for those who use a large soldering iron while working. It will make the job much easier because it aligns your hand just right to the tip of the iron. You are not confined in any one position and you can access every solder seam with ease.

This item has a nice weight, which tells us that it is built solid enough to handle any tough situation you may put it up against.

For one, it’s compatible with Weller WP35 irons, so it should be no problem finding this same sort of metal. Additionally, the funnel shape is perfect for guiding your tool to the lock ring – no need to hassle as much with avoiding direct contact on sensitive parts of your precision instrument!

And most importantly, at 1 pound and 8 inches high, this durable hunk of plastic can easily take any amount of abuse you throw its way without going anywhere or changing alignment.

Pros

- Sturdy;

- Good interface with the Weller WP35 irons;

- Well-shaped funnel;

- Made with durable plastic;

Cons

- Not heavy enough for some extra-large irons;

The Weller PH60 stand is an excellent purchase if you’re interested in doing electronics work that requires a good soldering iron.

The Buyer’s Guide

What is a Soldering Iron Holder?

A soldering iron holder is a device that helps to protect your hands from heat and burns, while also providing stability for the tool. Soldering irons are heated metal tools with an electric cord attached used in electrical work or other fabrication projects such as jewelry making. The temperature of the tip can reach up to 700 degrees Fahrenheit. This means it would be very difficult to pick up an exposed hot surface without protection – so using a solder pad holder will provide both safety and convenience!

A good quality holder should have two points: one at the end of each arm, which allows you to “grip” onto either side of the solder point on opposite sides. It may seem like common sense but too many people use these without thinking about the safety issues. Most soldering stations come with a holder, but check to be sure.

Some holders come in a variety of colors, but most are black or gray to help with heat transfer and not add any additional color into your work area – which can be distracting! These products also have non-slip pads on one side so that they stay put while you’re working.

The last thing you want is for this tool to slip right out of your hands because it was too cold, sweaty, greasy, covered with solder (which dries and sticks) etc., even if it happens just once. Of course, accidents happen sometimes no matter how careful we try to be – but using quality tools helps reduce those risks as much as possible. And keep in mind that a quality holder will last for years and years, so you’ll be getting your money’s worth.

How to Use a Soldering Iron Holder?

A soldering iron holder is a very useful tool to have in your workroom. It keeps the solder hot while you are working on another part of the product, which will save time and energy spent reheating it again and again. They also protect delicate surfaces from damage caused by excess heat exposure.

The most common way these holders are used is with a ceramic or metal clamp that attaches either below or above the device being worked on. The other end rests securely against an upright surface such as a tabletop and can be slid. So that its height matches up with what needs to be clamped down tightly without touching any objects nearby (that may be damaged). A good practice for using this type of stand would be when soldering cables to the PCB.

There is also a type of soldering iron holder that’s designed to hold the device in place and not be touched with any other part of your body. It works best when doing work on delicate surfaces like circuit boards or electronic components where you don’t want to risk damaging it while holding it steady for soldering. This design helps keep heat away from anything else nearby, making them perfect tools for working on small devices without worrying about touching something and causing damage.

FAQ

How to make a soldering iron holder?

A soldering iron holder is a safe way to store your heated tool when you are not using it. You can make one out of any material that will withstand high temperatures such as metal or stone, and they typically have holes on the back so that you may easily hang them up in an accessible location. It’s also possible to buy pre-made holders for less than $20 from many hardware stores.

First, cut two pieces of three-inch wide pine boards (one at five inches long – this will be the bottom), then screw together the two resulting rectangles into an L shape; this forms the bottom of your holder.

Next, cut two pieces of five-inch wide pine boards (one at four inches long – this will be the top), then screw together the two resulting rectangles into an L shape; this forms the top of your holder.

First, you need to drill holes on both sides of the board. Make sure they are close to the end on either side and about one-third from the bottom on each long side so that when you hang it up, it won’t fall over. The holes should be 3 inches apart based on where they are needed.

Tip: It’s helpful to make two holders at once since they are identical and you can use one while your other is drying in order to avoid wasting time.

How to assemble a soldering iron holder?

To assemble a soldering iron holder, first determine the length of your cord. If you have an extension cord already attached to the end of it and don’t want to cut that off then measure from where you plug into the wall outlet or power strip down to where you will be using your tool on its own.

Cut this measurement in half (or whatever length is appropriate for what we are going to do) and add on about 12 inches extra so there will be some room at either side when threading through our wire holders. You should now have two equal lengths- one with no plug still dangling at the end if desired as well as another part that has been stripped back by cutting away excess insulation and exposing bare copper wiring.

Do I need a sponge for my soldering iron holder?

A sponge is not necessary for a soldering iron holder. However, it can be helpful to clean the tip of your solder or keep an area moist while you’re working. If you do not want to use a sponge, cotton balls are often used instead. Soldering sponges can be expensive and it’s cheaper in the long run if you opt for using materials that are more affordable.

How do you protect the tip of a soldering iron?

Soldering iron tips are one of the most sensitive and delicate parts of a soldering tool. To ensure they last for as long as possible, there are various ways to protect them from damage caused by things like heat, moisture, or electricity.

One way is to remove it completely with a spudger – this will allow you access to solder connections not accessible through holes in circuit boards. Another common method is using flux paste (or rosin) which protects against oxidation during soldering and helps remove any build-up that occurs on contact sites after use.

Solders can also be used – these act similarly but require more care when removing particles due to their sticky nature. Although it’s important to remember that metal fumes may still be released into the air.

Lastly, you can also use a soldering iron holder that typically features an insulated grip with heat-resistant material and ventilation slots or grills to disperse steam. This ensures the tip is protected for safe handling while in storage so it doesn’t come into contact with other metal objects like screwdrivers that might cause damage without proper care.

How often should I tin my soldering iron?

Tinning a soldering iron is important to prevent oxidation of the tip. You should tin your soldering iron every 20 hours of use, or at least once a week for best results. Tinning prevents corrosion and makes sure that solder will flow smoothly from the nozzle onto any surface you want it on.

It is possible to tin your soldering iron without a holder, but it will take some time and effort. Tinning with an unsoldered holder can be done by wrapping the tip in solder or flux-coated cloth and heating for about five minutes. The downside of not using a soldering iron holder while tinning is that you may burn through whatever surface you are trying to solder because it takes much less heat to melt solder than metal.

How do I keep my soldering iron from oxidizing?

Here is what you should do:

- Don’t expose your soldering iron to the air for long periods. If it’s been out in the open, wipe off any excess solder or flux before storing them away;

- Keep your work environment clean and free from dust. This will go a long way towards preventing contamination on components;

- Avoid letting your soldering iron come into contact with any chemicals, solvents or flammable materials;

- Keep your soldering iron in an enclosure when not using it to prevent oxidation and contamination from exposure to the air;

What is a solder tip activator?

A solder tip activator is a small device that connects to the soldering iron’s power supply and heats up in order to allow for cleaner, more fluid application of molten (liquid) lead-based solder. The benefit of using an activator over just holding your finger on top of the solder while it cools down is that you will be able to work faster because you won’t need as much time between consecutive applications.

A typical one consists of two metal poles with a spring-loaded contact point at their tips that sit against each other when not activated but are pulled apart by screwing them together once they have been brought near enough to heated contacts on either end. As well as a heat-resistant surface mat or clamp to hold the soldering tip in place.

Can you use steel wool to clean a soldering iron?

Yes. The best way to clean a soldering iron is with steel wool and water or alcohol. However, you can also use rubbing alcohol for wire cleaning as well. Make sure that the wood of your holder doesn’t have any cracks where water could sweep in because it will damage the wood over time.

Use only 100% cotton (or other natural) fiber steel wools since synthetic fibers like nylon may contain plasticizers that dissolve into oil-based solvents such as gasoline or kerosene, contaminating them and making them unusable for future soldering jobs; don’t use steel wool with copper or brass parts.

To clean your soldering iron, you will need to remove the protective coating from its tip and scrape off any residue that has built up on the metal coil. Then rub it with a used portion of cotton steel wool until all corrosion is removed, being careful not to scratch or bend the delicate tips of an internal heating element within. Finally, dip in rubbing alcohol and wipe dry before storing away for later use.

Video Tutorial: a Soldering-Iron Stand, a Tip-Cleaner and a Ceramic Board

Final thoughts

All of us want to work with our hands as much as possible – but it is also important not to forget about safety! Soldering iron holders are designed just for this purpose. They keep the soldering iron secure in one hand while still providing a good grip on both sides of the solder point at once. This ensures that there won’t be any accidents when working with these hot tools!