Customer’s Choice: the Best Rated Soldering Iron Testers

[survey_answers id=”217993225″ style=”plain” data=”score”] users answered this survey. Please help us improve this review!

[survey_answers id=”217993225″ style=”piechart” legend=”true”]

This review is dedicated to testers of soldering irons. It includes the results of my tests and experience over the years. I think my colleagues will agree that testers can be quite useful.

When should you apply the tester for soldering irons?

Classic soldering irons with non-replaceable and interchangeable rods are checked by the inclusion of 220 V (or 127 V) in the network and external inspection. The soldering iron’s heating element is considered ready for service if the temperature of the outer surface of its metal parts (after 30 – 40 seconds after turning on an iron) will increase by several degrees during tests.

The heating element’s integrity is sometimes checked by observing a spark in the socket of switching a soldering iron on and off. The service life of the tool’s heating element is also verified by checking the current flow or by measuring the resistance of the heating element with the special device called a tester. A good tester can cope with all these tasks and verify the use of your soldering iron for small or challenging tasks.

Why is the soldering iron’s temperature testing required?

A soldering iron tip’s measuring device is required for the accurate selection of soldering irons. One of the soldering rules is that the tip temperature should be higher than the melting point of the solder. However, if it is much higher, then difficulties can appear and it may lead to the solder can go into a fluid state.

Testers for measuring the temperature of a soldering iron tip are electronic devices that can quickly and accurately show the required information before using the tool. They use a heating element to measure the soldering iron tip’s temperature. Chromium and aluminum, whose thickness is tenths of a millimeter, are used as sensitive elements in testers. Usually, testers show the required information in less than a second.

Features of the best soldering iron testers

I recommend buying a device that has a large digital display. Also, make sure that the tester’s heating part is coated with a special alloy to avoid corrosion. This tool uses a quick replacement of sensitive elements, which helps to speed up the work during breakouts. Automatically, the shutdown mode happens 3 minutes after the last performed action. Sensors must have a long service life.

According to my experience, it is better to choose a soldering iron tester with such tech parameters:

- The temperature range for testing is 0-12920F;

- The maximum error is 37 – 41 0F, depending on the measuring range;

- The weight is about 120 g;

- The display’s resolution must be at least 3.5;

My preferences for using the best soldering iron testers:

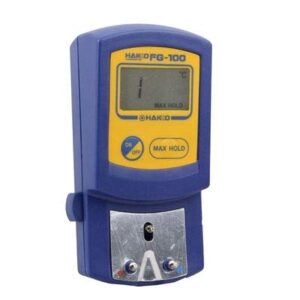

- Hakko testers are very popular in this niche. It includes a multi-adapter and sensor, with ground clip;

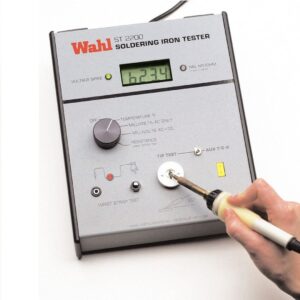

- Wahl is good for testing the heating element’s temperature from 122 to 2372 0F. It has a warning light and ESD safe construction;

- I can recommend a Lorchwise tester for lead-free solder, with easy measurement and compact size design;

- Hakko is another tester of good quality that is extremely easy to use. Check its awesome LCD display;

- Beioust is a tester with an ergonomic design and automatic measurement system. But it is made of plastic, so check it thoroughly before buying;

Video Tutorial: A look inside a “Hakko” soldering iron tip temperature tester

Do you use soldering iron testers? Share your experience here, ask any questions – I will read and answer all comments. Thanks to regular readers of SolderingIronGuide! Subscribe to follow the new reviews and updates.

Hakko is generally a good choice and the FG-101 in particular, is a soldering iron tester I like a lot. Multi-adapter, ground clip and sensor (10 pcs/set) make this a more than decent option. The display could be larger but it doesn’t bother me that much.

If you have more than a passing interest in electronics, you’ll probably need a soldering iron at some point. Yes, you can get into some minor points with a breadboard, but if you want to truly get into DIY electronics, you’ll need a soldering iron.